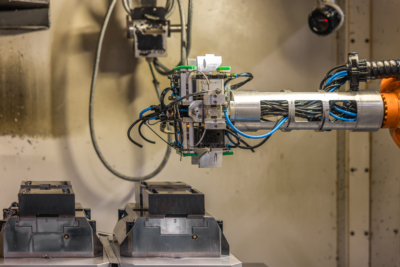

Des cellules robotisées, des machines interconnectées, des services fonctionnant en

« paperless » … nous innovons chaque jour pour rendre notre usine toujours plus performante.

Nous sommes régulièrement à la recherche de nouveaux collaborateurs. Découvrez nos postes vacants.

découvre ici ton nouveau job